selection equipment size of single roll crusher

mclanahan

McLanahan Single Roll Crushers

mclanahan

Factors to Consider When Selecting the Proper Roll

Material to Be CrushedFeed SizeRequired Product SizeTooth ConfigurationFlowabilityThroughput CapacityNext to be considered is the required product size When taking this into account, you must also refer back to the feed size to see if the ratio of reduction requires multiple stages of crushing A good rule of thumb for singlestage crushers is that a Single Roll Crusherprovides up to a 6:1 ratio of reduction and a Double Roll Crusher provides up mclanahan

McLanahan Roll Crushers

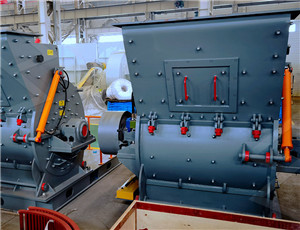

Single Roll Crushers Single Roll Crushers are typically used as primary crushers that provide a crushing ratio of up to 6:1 They crush materials such as ROM coal, mine

Roll Crusher an overview ScienceDirect Topics

Conventional singleroll crushers use a simpler toothedroll design, and are commonly used to reduce coal to approximately a 2–3in (5–8 cm) top size The capacity of the

Selecting the Right Crushing Equipment AggNet

2015年10月28日 Singletoggle jaw crushers have better feed acceptance capability than the corresponding doubletoggle crushers Jaw crushers are reliable, robust machines, offering a 6:1 reduction ratio in most materials,

Roll Crushers ScienceDirect

2016年1月1日 Equation (62) can be used to select the size of roll crushers for specific requirements For nip angles between 11° and 17°, Figure 63 indicates the roll sizes

Heavyduty single roll crusher Magaldi

The product family consists of models of different sizes (27’’, 54’’, 67’’, 81’’) depending on the required final particle size and capacity Working concept Magaldi SingleRoll Crusher features a toothed roll assembly, which

Crushers Selection Guide: Types, Features, Applications

Primary crushing operations takes boulder size feeds (20 to 100 inches) and reduces the material to secondary crusher feed size (1 to 20 inches) or mill feed size (05 to 3 inches) This video illustrates single and double

Downstream Crushing Options for Secondary, Tertiary

2021年4月12日 Depending on the design, Roll Crushers have a reduction ratio of 6:1 (single roll and the top stage of the Triple Roll) and 4:1 (double rolls) They are great for handling soft to medium hard, slightly abrasive

Roll Crushers ScienceDirect

2016年1月1日 Abstract This chapter deals with the designs and operation of different types of roll crushers Two main types are indicated The first type where the rolls are